With the rapid development of Chinese economy, the enlarging of the scale of enterprises, the extension of the industry chain as well as the high level of the detailed management, equipment management department should set up a suitable management and control mode so as to make the assets management turn to be detail-oriented. To satisfy the demands of the rapid development and enlargement of the enterprises, equipment management department have to manage the enterprise’s assets well so as to achieve the goals of safer, reliable, efficiency and ROI?

Challenge

1.How to normalize the business flow, data standard and code of equipment management?

2. How to set up the budget target of enterprise equipment assets management and realize budget analysis for enterprise level?

3. How to manage the suppliers and promote enterprise centralized purchase management so as to lower the procurement costs?

4. How to manage all the conditions of the equipment and the assets, especially the floating assets?

5. How to build maintenance plans for key equipment comprehensively and keep monitoring?

6. How to set up an E-warehouse to sharing and allocating all the resources reasonably?

7. How to implement the performance evaluation of enterprise equipment assets, measures the level of equipment management, finds problems and keeps continuous improvement?

Summary

An organic and integrated information management system can be set up. It can support 3 main types of group management mode, like investment oriented group, strategic oriented group and operation group. It can manage all the concerned parts, such as budget, plans, standards, security, key resources. Basic status as well as running conditions can be controlled. Basic management will be normalized and strengthened. Management innovation and experience’s accumulation and sharing are promoted. It can provide basic information for scientific decisions of assets management. Finally, it can help assets management to achieve a high level of safe, reliable, efficiency and ROI.

Values

1. The system can help to reform and optimize the equipment management process, which will turn to be a standardized, normalized and detailed process. In this way, general executive efficiency can be improved.

2. The system can help to set up a database, which includes the fundamental as well as the process data, and achieves data sharing. It is very convenient for searching, counting and analyzing and very safe and stable. It can also avoid the loss of information and data caused by personnel changes.

3. The system can help to improve the reliability and availability of equipment and reduce the shutdown time. The general efficiency of equipment is improved.

4. The system can help to integrate and allocate technology resources, human resources, capital resources, and spare parts resources reasonably so as to reach a maximum use of the resources.

5. The system and the additional tools can help to strengthen the control of the on-site. Condition of equipment can be controlled and maintenance process can be traced. All the records will be provided to the maintenance information analysis for equipment asset management accurately and timely.

6. The system can realize linkage mechanisms with purchase, stock and consumption in spare parts management. It can lower the inventory as well as the cost of the spare parts. And also, it can coordinate with related principles to enhance the spare parts management.

7. The system can help to develop performance indicators and set up an evaluation system. It can provide scientific suggestions for the decisions of the enterprise with the data processing ability.

8. The system can help to cultivate a modernized maintenance and management team so as to satisfy the requirements of the guarantee of the production.

9. …….

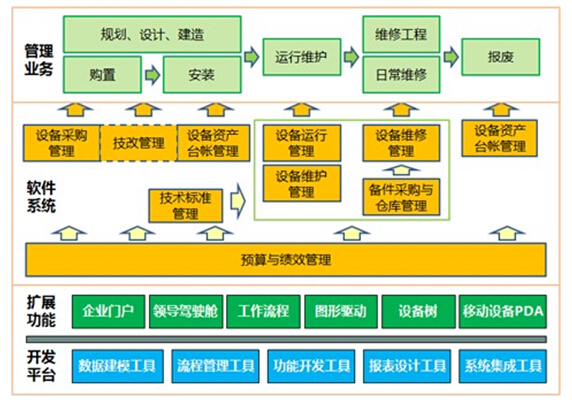

管理业务:Business 规划、设计、建造:Planning,Designing & Constructing 购置:Purchase 安装:Install 运行维护:Operation & Maintenance 维修工程:Overhaul 日常维修:Daily Maintenance 报废:Scrapped

软件系统:Software System

设备采购管理:Purchase management

技改管理:Techniques Improvement Management

设备资产台账管理:Ledger Management

设备运行管理:Operation Management

设备维护管理:Maintenance Management

设备维修管理:Repairing Management

备件采购和仓库管理:Spare Part Purchase & Warehouse Management

设备资产台账管理:Ledger Management

预算和绩效管理:Budget & Performance Management

扩展功能:Extension Function

企业门户: Equipment Management Portal

领导驾驶舱:Leader Control Space

工作流程:Working Process

图形驱动:Graphics Drivers

设备树:Tree-Structure Equipment Management

移动设备PDA:PDA

平台开发:Platform Development

数据建模工具:Data Modeling Tool

流程管理工具:Workflow Management Tool

功能开发工具:Functional Development Tool

报表设计工具:Report Designer Tool

系统集成工具:Qsys

Structure

Establishing an enterprise-level equipment management system including purchase management, ledger management, techniques standard management, operation management, maintenance management, repair management, inventory management, budget and performance management and so on.

After analysis of the business contents, some featured functions could be applied, such as configuring equipment management portal, designing leader control space, displaying working process, organizing tree-structure equipment management, guiding working by graphics and being applied by mobile devices.

An excellent development platform is able to meet the demands of the development of business, which means it could provide tools like data modeling tool, workflow management tool, functional development tool, report designer tool and Qsys.

Key point

Budget Management

Budget management includes budget planning, budget controlling, budget adjusting and analyzing. It can help enterprise to strengthen the planning, controlling and analyzing of the operation and manage and control the daily business management activities of the enterprise efficiently.

Purchase Management

It includes important phases of the purchase, like equipment purchase, spare part purchase, outsourcing services purchase and so on. It can finally realize the comprehensive decision-making and compliance management of the purchase process.

Ledger Management

It includes establishment of equipment ledger, equipment change ledger. It could solve the problems between equipment and fix assets and equipment and equipment, so as to lay solid foundation for the operation, repairing and maintenance of equipment.

Techniques Standard Management

Techniques standard management mainly includes establishing a database on techniques, management, and operation and maintenance standards. The database can be revised, supplied and controlled with the knowledge accumulation during operation and maintenance. At last, the database of equipment can be managed well.

Operation Management

The aim of operation management is to master the equipment running condition dynamically. It is one of the main parts of equipment technology management. With all kinds of management principles, equipment operation management, which records the histories and monitors the current situation of the equipment, can analyze the reliability and economy of the running equipment, and supply scientific base for reasonable maintenance measures.

Maintenance Management

Maintenance management mainly consists of lubricating and service. It can help to set up a lubricating and service alarming system, which could create plans automatically and feed back the information swiftly.

Repairing Management

Combined with maintenance technique standards, equipment maintenance operation standard and order management, it can set up a modernized maintenance system focused on normalized maintenance and preventive maintenance.

Spare Part & Inventory Management

It mainly manages the enterprise level inventory. It can make the process of purchasing, storing and consuming working smoothly. To set up a data module of price, consuming, and inventory, it can do scientific analysis so as to provide timely and reliability data as reference. It consists of warehouse management, applying management, returning management, alarming management, scrapped management, zero inventory spare parts management and corresponding analysis. It works with purchase management to minimum the inventory which could satisfy the requirements of maintenance.

Special Equipment & Measuring Equipment Management

Special equipment and measuring equipment are managed according to the national management principles. It includes the ledger establishing, alarming, checking plans and checking results of all kinds of special equipment and measuring equipment.

KPI Management

The process of choosing KPI indicators is to systematically analyze and scientific resolve of the creating process of strategic and value, and develop key indicators from different levels and units. The indicators could make different levels communicate well and reflect the performance of different worker directly. It can lay solid foundation for the improvement of the enterprise.

System Management

It mainly consists of organization and structure management, order allocation management, system integration and link management, graphics management.